Gold Studding

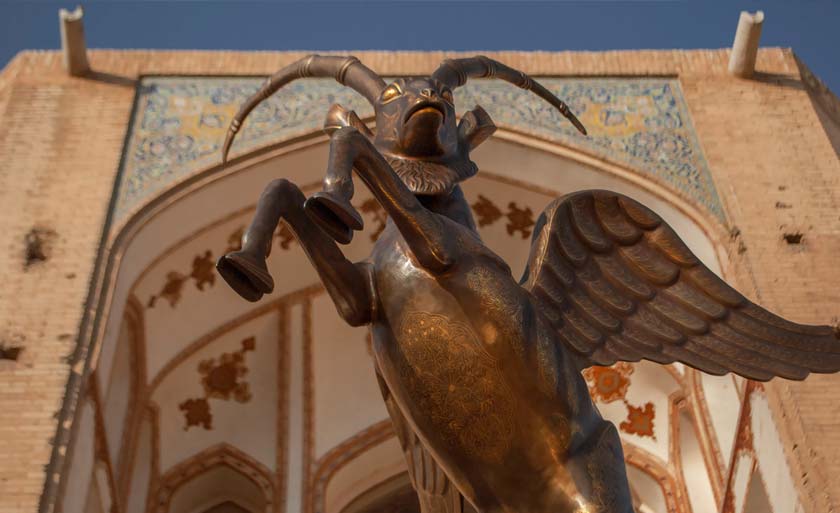

The art of making designs on steel bodies by means of very thin threads of gold is called gold studding. In the past gold studding was done on wood, also inlaying or undulating steel used to be done by gold but today the main purpose of gold studding is decoration of steel objects and particularly animal statues which have a religious significance and are carried in the mourning ceremonies. This method of gold studding has been known in Europe in the medieval centuries, because the details of gold studding on war wares, armors, etc. have been explained in the books which are related to that period. Preparation of the understructure which is in the form of statues like the shapes of lion, gazelle, peacock, etc. is one of the main stages. The metal which is usually used is steel and all the shaping process is done manually by hammering. At the end, all the pieces are attached together and the work-piece is polished.

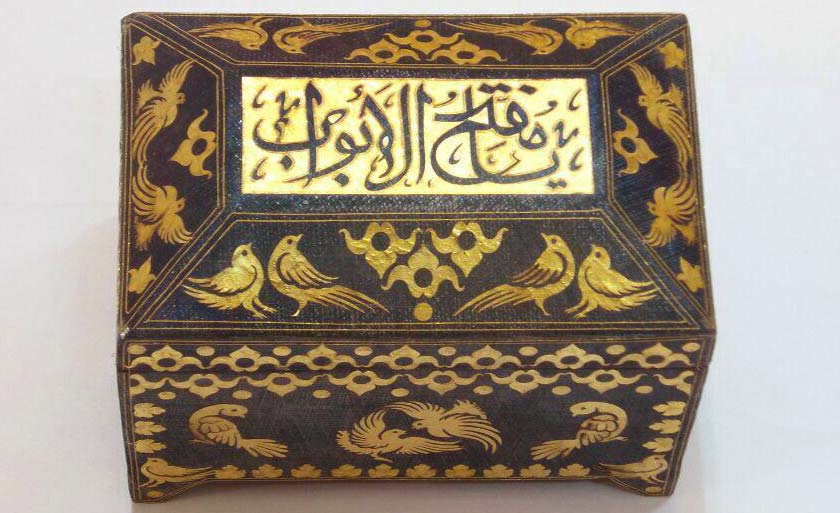

Of the other important understructures on which the gold studding is done is the mourning flag carried in religious ceremonies. In addition to metal blades there are also the figures of some animals and birds which are attached on the flags after being made and gold studded. The main tool used in this art is a special knife by which the craftsman makes dentate the places in which gold is to be studded, then a golden string called tinsel (Naghdeh) with a thickness of 0.007 cm is put in the cleft places and hammered by a gold-studding hammer. Finally, the surface of the work-piece is glazed by a piece of agate or jade stone. In addition to making it bright, this action causes more attachment of the golden string to the steel body surface. Having finished the gold studding work, a special ink is rubbed on the steel and after being heated its entire surface is blackened. Then, it is polished with a polisher so that the work-piece is polished completely. The more the delicacy of the designs and paintings and at the same time, the more precise and cleaner the hammering process, the better the quality of the product.

Leave a Reply

Want to join the discussion?Feel free to contribute!